SAFuelsX Sustainable Aviation

Home-grown sustainable fuels, our North Dakota way.

We shall install and operate a renewable fuels production facility in a safe manner to assure quality, reliable products to our customers. We strive to build lasting, mutually beneficial relationships with our suppliers, contractors and employees willing to take on our mission as their own.

Our Purpose

We are committed to showing that it is practical, profitable, and sustainable to fight climate change. When our farmers grow oil-producing crops they are removing carbon dioxide from the atmosphere. When our product is burned as fuel, this carbon dioxide is replaced into the atmosphere, not added to it. With our commercial, Federal, State, and community partners we are commercializing what up until now has been merely a concept.

Our Project

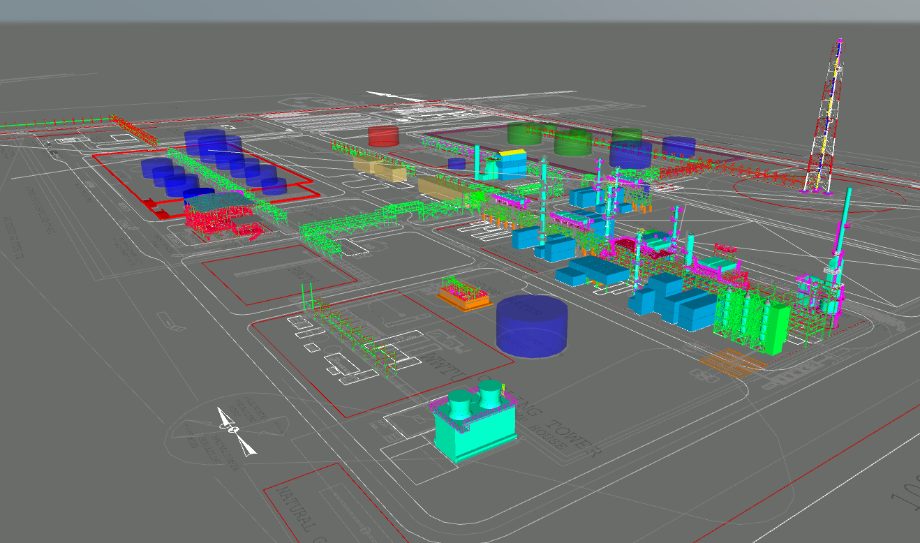

SAFuelsX Sustainable Aviation project now advances to the FEL3 stage with a Engineering, Procurement and Construction (EPC) contractor. The preliminary design moves to full design, including development of exact specifications for the equipment to be purchased and installed. With a nameplate production of 100 million gallons per year or approximately 6,500 barrels per day, would be considered a midsize renewable fuels production facility. Hydrogen will be produced on-site in amounts only as needed and consumed immediately in the adjacent hydrotreated vegetable oil (HVO) unit. Both process units will use Haldor-Topsoe’s reactor technologies, but in a unique configuration design to maximize jet fuel production.

A modular design approach will be undertaken to shorten the on-site construction period and accommodate challenges of mid-winter work in North Dakota.

The modern biofuels production facility will bring economic opportunities to the northwest region of North Dakota, disproportionately impacted by the decline in oil-drilling activity. Using USDA standard multipliers, it is expected each of the 150 jobs it creates, either directly as an employee or indirectly as a contracted staff, more than 4 additional jobs will be created in the local economy. For every dollar of earnings at the plant, an additional amount will circulate through the local economies.

Likely as important to the regional economy will be the new demand for additional agricultural products. Using soybean oil and/or canola oil as primary feedstocks, these vegetable oils will be converted into fuels as direct replacements for the fuels we use today. SAFuelsX Sustainable Aviation also creates an immediate demand and opportunity for others to site and build one or more seed crushing plants in the area.

AIC Energy Corp is committed to providing energy to America in a safe, sustainable, and innovative facility, contributing to North Dakota’s economic prosperity and the world’s energy transition.

Our Plant

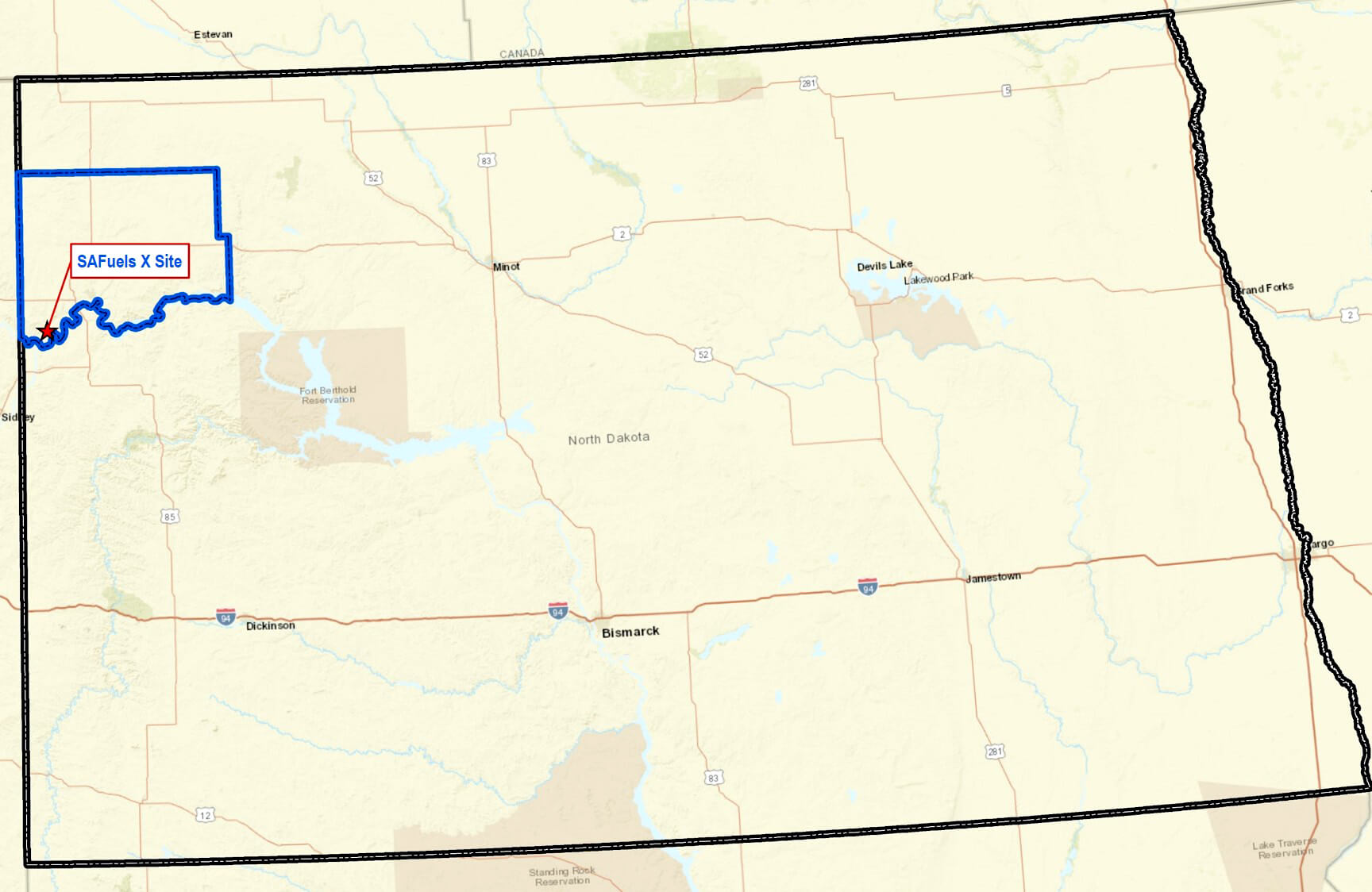

Over 87 acres of land was purchased south of 42nd Street in the Trenton Industrial Park near the Savage Services rail port. While both the vegetable oil feed and finished products are expected to arrive and depart by rail and subsequently piped to the plant, an on-road traffic study will be conducted.

Construction will require an average of 150 people per day with peak employment at 300. The plant will be built with North Dakota union labor.

Our Products

Sustainable Aviation Fuel (SAF) – renewable jet fuel to either commercial or military Jet A1 specifications depending on demand, contracts, and spot market prices. The principal market for both jet fuels will be the Department of Defense although discussions with several commercial airlines are also underway. Our renewable aviation fuel will require blending to make it an approved Sustainable Aviation (SAF) Fuel, at least until the jet engine and aircraft manufacturers make changes to their systems. Eventually our product will be usable as a direct drop-in replacement for fossil-sourced jet fuel, doubling the reduction in carbon emissions for each mile flown. This is being worked on by the manufacturers now, and is expected in the near, not distant future.

Renewable Diesel Fuel – both renewable, low-sulfur diesel #1 and low-sulfur diesel #2. Operation will be flexible to change yield of each as the market economics suggests. This flexibility also insulates the plant from dips in diesel fuel or jet fuel demand. Renewable diesel, not biodiesel. Renewable diesel fuel does not require blending before use. It is a direct drop-in product. As a “drop-in replacement” for traditional petroleum on-road diesel, it meets the same state-mandated product specifications. Full-time use of these fuels will not require any retrofitting of vehicle engines or fueling infrastructure, nor endanger vehicle warranties.

Renewable Naphtha – naphtha is like gasoline although it does not meet final product specification to make it suitable for retail sales. It can be used as a chemical feed-stock, used as a fuel-ethanol denaturant, or blended with other naphtha’s to make gasoline. Our target, however, is the Green Plastics industry who want to use this renewable naphtha to make non-fossil sourced plastics for all imaginable plastic products.